Products & Service

-

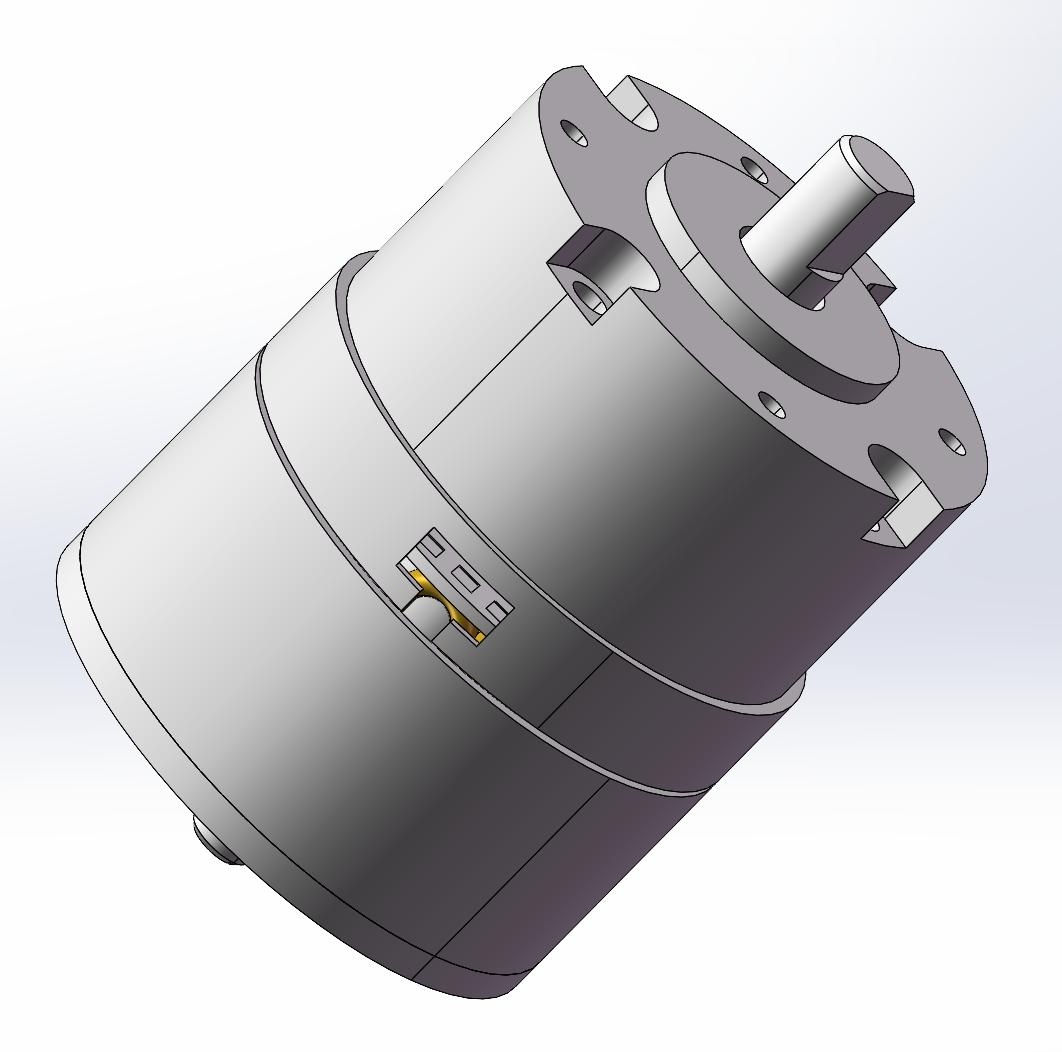

Induction motor-Y97125

Induction motors are engineering marvels that utilize the principles of electromagnetic induction to provide powerful and efficient performance in a variety of applications. This versatile and reliable motor is the cornerstone of modern industrial and commercial machinery and offers many advantages that make it an indispensable component in countless systems and equipment.

induction motors are a testament to engineering ingenuity, providing unparalleled reliability, efficiency and adaptability in a variety of applications. Whether powering industrial machinery, HVAC systems or water treatment facilities, this vital component continues to drive progress and innovation in countless industries.

-

Induction motor-Y124125A-115

An induction motor is a common type of electric motor that uses the principle of induction to produce rotational force. Such motors are commonly used in industrial and commercial applications because of their high efficiency and reliability. The working principle of an induction motor is based on Faraday’s law of electromagnetic induction. When an electric current passes through a coil, a rotating magnetic field is generated. This magnetic field induces eddy currents in the conductor, thereby generating a rotating force. This design makes induction motors ideal for driving a variety of equipment and machinery.

Our induction motors undergo strict quality control and testing to ensure stable and reliable product quality. We also provide customized services, customizing induction motors of different specifications and models according to customer needs.

-

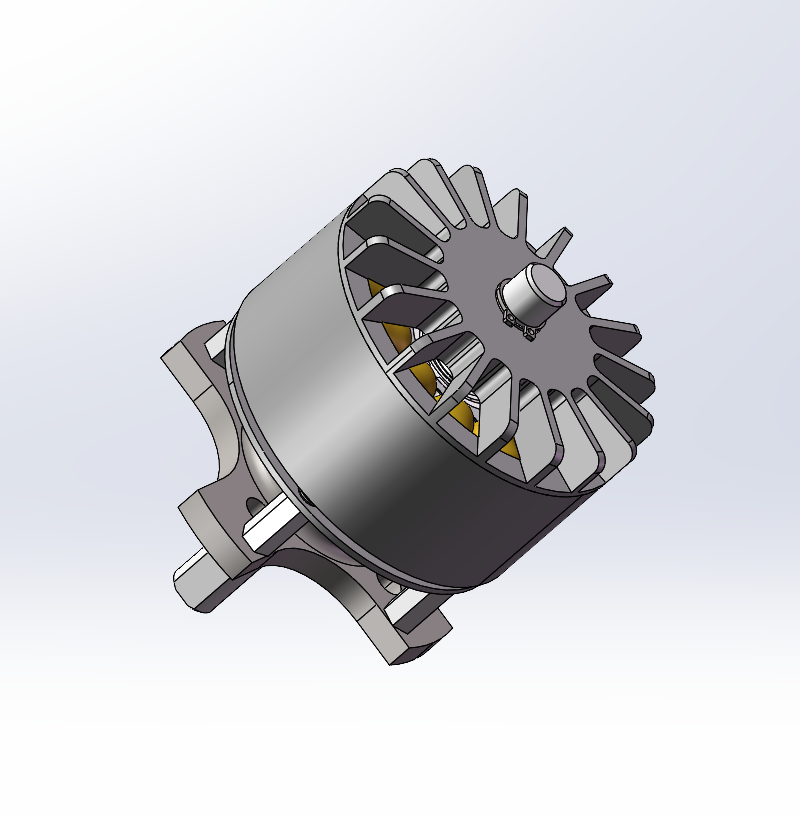

Outer rotor motor-W4215

The outer rotor motor is an efficient and reliable electric motor widely used in industrial production and household appliances. Its core principle is to place the rotor outside the motor. It uses an advanced outer rotor design to make the motor more stable and efficient during operation. The outer rotor motor has a compact structure and high power density, allowing it to provide greater power output in a limited space. In applications such as drones and robots, the outer rotor motor has the advantages of high power density, high torque and high efficiency, so the aircraft can continue to fly for a long time, and the performance of the robot has also been improved.

-

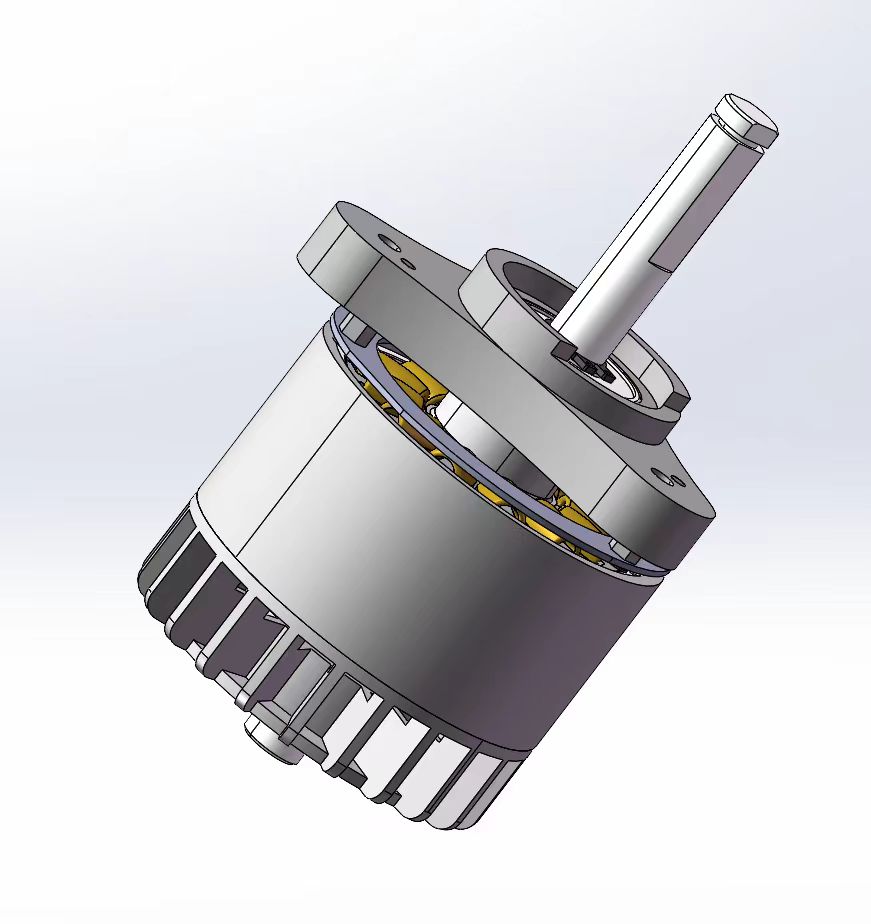

Outer rotor motor-W4920A

Outer rotor brushless motor is a type of axial flow, permanent magnet synchronous, brushless commutation motor. It is mainly composed of an outer rotor, an inner stator, a permanent magnet, an electronic commutator and other parts, because the outer rotor mass is small, the moment of inertia is small, the speed is high, the response speed is fast, so the power density is more than 25% higher than the inner rotor motor.

Outer rotor motors are used in a wide range of applications, including but not limited to: electric vehicles, drones, home appliances, industrial machinery, and aerospace. Its high power density and high efficiency make external rotor motors the first choice in many fields, providing powerful power output and reducing energy consumption.

-

Induction motor-Y286145

Induction motors are powerful and efficient electrical machines that are widely used in a variety of industrial and commercial applications. Its innovative design and advanced technology make it an important part of various machinery and equipment. Its advanced features and rugged design make it an indispensable asset for businesses looking to optimize operations and achieve sustainable energy use.

Whether used in manufacturing, HVAC, water treatment or renewable energy, induction motors deliver superior performance and reliability, making them a smart investment for businesses across a variety of industries.

-

Outer rotor motor-W6430

The outer rotor motor is an efficient and reliable electric motor widely used in industrial production and household appliances. Its core principle is to place the rotor outside the motor. It uses an advanced outer rotor design to make the motor more stable and efficient during operation. The outer rotor motor has a compact structure and high power density, allowing it to provide greater power output in a limited space. It also has low noise, low vibration and low energy consumption, making it perform well in a variety of application scenarios.

External rotor motors are widely used in wind power generation, air conditioning systems, industrial machinery, electric vehicles and other fields. Its efficient and reliable performance makes it an indispensable part of various equipment and systems.

-

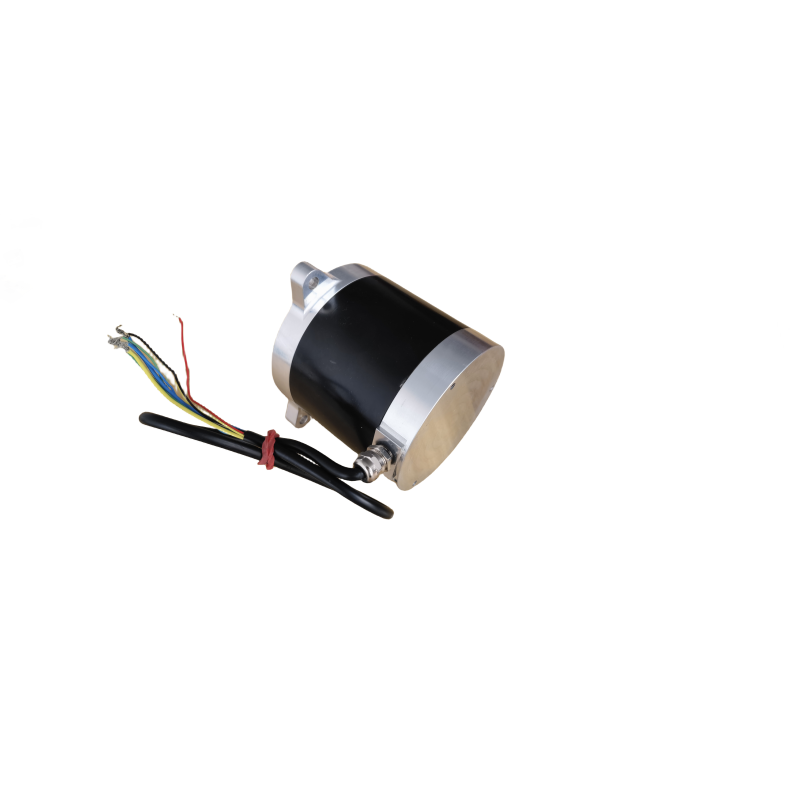

Electric Forklift Brushless DC Motor-W100113A

This kind of brushless DC motor is a high-efficiency, low-noise, low-maintenance motor that is widely used in industrial electric vehicle. It uses advanced brushless technology to eliminate carbon brushes in traditional DC motors, reducing energy loss and friction, thereby improving efficiency and performance. This motor can be controlled by the controller, which controls the speed and steering of the motor according to the user’s needs. This motor also offers high reliability and long life, making it a first choice in many applications.

This brushless motor is characterized by its high efficiency, reliability and low maintenance cost, which meets the substantial requirements of the majority of users for the brushless motor.

-

Stage Lighting System Brushless DC Motor-W4249A

This brushless motor is ideal for stage lighting applications. Its high efficiency minimizes power consumption, ensuring extended operation during performances. The low noise level is perfect for quiet environments, preventing disruptions during shows. With a compact design at only 49mm in length, it integrates seamlessly into various lighting fixtures. The high-speed capability, with a rated speed of 2600 RPM and a no-load speed of 3500 RPM, allows for quick adjustments of lighting angles and directions. The internal drive mode and inrunner design ensure stable operation, reducing vibrations and noise for precise lighting control.

-

Fast Pass Door Opener Brushless motor-W7085A

Our brushless motor is ideal for speed gates, offering high efficiency with an internal drive mode for smoother, faster operation. It delivers impressive performance with a rated speed of 3000 RPM and a peak torque of 0.72 N.m, ensuring swift gate movements. The low no-load current of just 0.195 A helps in energy conservation, making it cost-effective. Additionally, its high dielectric strength and insulation resistance guarantee stable, long-term performance. Choose our motor for a reliable and efficient speed gate solution.

-

Wheel motor-ETF-M-5.5-24V

Introducing the 5 Inch Wheel Motor,engineered for exceptional performance and reliability. This motor operates on a voltage range of 24V or 36V, delivering a rated power of 180W at 24V and 250W at 36V. It achieves impressive no-load speeds of 560 RPM (14 km/h) at 24V and 840 RPM (21 km/h) at 36V, making it ideal for a wide range of applications that require varying speeds. The motor features a no-load current of under 1A and a rated current of approximately 7.5A, highlighting its efficiency and low power consumption. The motor operates without smoke, odor, noise, or vibration when unloaded, guaranteeing a quiet and comfortable environment. The clean and rust-free exterior also enhances durability.

-

W6062

Brushless motors are an advanced motor technology with high torque density and strong reliability. Its compact design makes it ideal for a variety of drive systems, including medical equipment, robotics and more. This motor features an advanced inner rotor design that allows it to deliver greater power output in the same size while reducing energy consumption and heat generation.

Key features of brushless motors include high efficiency, low noise, long life and precise control. Its high torque density means it can deliver greater power output in a compact space, which is important for applications with limited space. In addition, its strong reliability means it can maintain stable performance over long periods of operation, reducing the possibility of maintenance and failure.

-

Blower Heating Brushless DC Motor-W8520A

A blower heating motor is a component of a heating system that is responsible for driving the airflow through the ductwork to distribute warm air throughout a space. It is typically found in furnaces, heat pumps, or air conditioning units.The blower heating motor consists of a motor, fan blades, and housing. When the heating system is activated, the motor starts and spins the fan blades, creating a suction force that draws air into the system. The air is then heated by the heating element or heat exchanger and pushed out through the ductwork to warm the desired area.

It is durable for harsh vibration working condition with S1 working duty, stainless steel shaft, and anodizing surface treatment with 1000 hours long life requirement requirements.