Brushed DC Motors

-

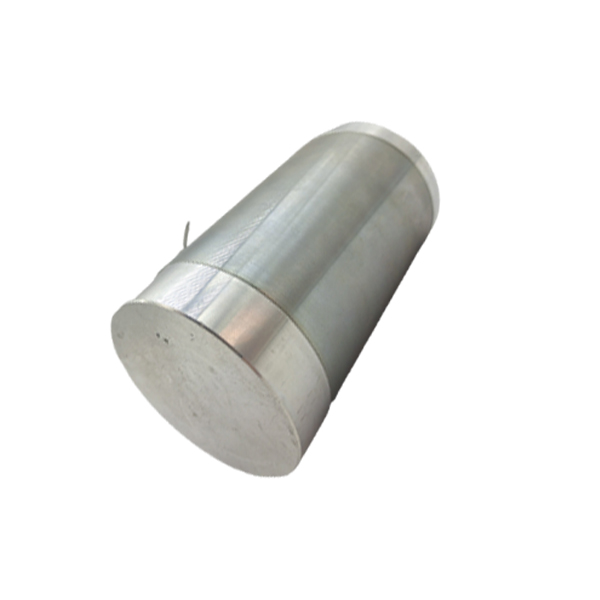

Robust Brushed DC Motor-D104176

This D104 series brushed DC motor(Dia. 104mm) applied rigid working circumstances. Retek Products manufactures and supplies an array of value-added brushed dc motors based on your design specifications. Our brushed dc motors have been tested in the harshest industrial environmental conditions, making them a reliable, cost-sensitive and simple solution for any application.

Our dc motors are a cost-effective solution when standard AC power is not accessible or needed. They feature an electromagnetic rotor and a stator with permanent magnets. The industry-wide compatibility of an Retek brushed dc motor makes integration into your application effortless. You can choose one of our standard options or consult with an application engineer for a more specific solution.

-

Robust Brushed DC Motor-D78741A

This D78 series brushed DC motor(Dia. 78mm) applied rigid working circumstances in power tool, with equivalent quality comparing to other big brands but cost-effective for dollars saving.

It is durable for harsh vibration working condition with S1 working duty, stainless steel shaft, and anodizing surface treatment with 1000 hours long life requirement requirements.

-

Seed Drive brushed DC motor- D63105

The Seeder Motor is a revolutionary brushed DC motor designed to meet the diverse needs of the agricultural industry. As the most basic driving device of a planter, the motor plays a vital role in ensuring smooth and efficient seeding operations. By driving other important components of the planter, such as the wheels and seed dispenser, the motor simplifies the entire planting process, saving time, effort and resources, and promises to take planting operations to the next level.

It is durable for harsh vibration working condition with S1 working duty, stainless steel shaft, and anodizing surface treatment with 1000 hours long life requirement requirements.

-

Motor used for rubbing and polishing jewelry – D82113A

The brushed motor is commonly used in various industrial and commercial applications, including jewelry manufacturing and processing. When it comes to rubbing and polishing jewelry, the brushed motor is the driving force behind the machines and equipment used for these tasks.

-

Robust Pump Motor-D3650A

This D36 series brushed DC motor(Dia. 36mm) applied rigid working circumstances in medical suction pump, with equivalent quality comparing to other big brands but cost-effective for dollars saving.

It is durable for harsh vibration working condition with S1 working duty, stainless steel shaft, and anodizing surface treatment with 1000 hours long life requirement requirements.

-

Robust Suction Pump Motor-D4070

This D40 series brushed DC motor(Dia. 40mm) applied rigid working circumstances in medical suction pump, with equivalent quality comparing to other big brands but cost-effective for dollars saving.

It is durable for harsh vibration working condition with S1 working duty, stainless steel shaft, and anodizing surface treatment with 1000 hours long life requirement requirements.

-

Smart Micro DC Motor for Coffee Machine-D4275

This D42 series brushed DC motor(Dia. 42mm) applied rigid working circumstances in smart devices with equivalent quality comparing to other big names but cost-effective for dollars saving.

It is reliable for precise working condition with S1 working duty, stainless steel shaft,with 1000 hours long life requirement requirements.

-

Reliable Automotive DC Motor-D5268

This D52 series brushed DC motor(Dia. 52mm) applied rigid working circumstances in smart devices and financial machines, with equivalent quality comparing to other big names but cost-effective for dollars saving.

It is reliable for precise working condition with S1 working duty, stainless steel shaft, and black powder coating surface with 1000 hours long life requirement requirements.

-

Robust Brushed DC Motor-D64110

This D64 series brushed DC motor(Dia. 64mm) is a small sized compact motor,designed with equivalent quality comparing to other big brands but cost-effective for dollars saving.

It is durable for harsh vibration working condition with S1 working duty, stainless steel shaft, and anodizing surface treatment with 1000 hours long life requirement requirements.

-

Robust Brushed DC Motor-D68122

This D68 series brushed DC motor(Dia. 68mm) can be used for rigid working circumstances as well as the precision field as motion control power source, with equivalent quality comparing to other big names but cost-effective for dollars saving.

It is durable for harsh vibration working condition with S1 working duty, stainless steel shaft, and anodizing surface treatment with 1000 hours long life requirement requirements.

-

Powerful Climbing Motor-D68150A

The motor body diameter 68mm equipped with planetary gearbox to generate robust torque, can be used in many fields such as climbing machine, lifting machine and so on.

In harsh working condition, it can be also used for as lifting power source which we supply for speed boats.

It is also durable for harsh vibration working condition with S1 working duty, stainless steel shaft, and anodizing surface treatment with 1000 hours long life requirement requirements.

-

Robust Brushed DC Motor-D77120

This D77 series brushed DC motor(Dia. 77mm) applied rigid working circumstances. Retek Products manufactures and supplies an array of value-added brushed dc motors based on your design specifications. Our brushed dc motors have been tested in the harshest industrial environmental conditions, making them a reliable, cost-sensitive and simple solution for any application.

Our dc motors are a cost-effective solution when standard AC power is not accessible or needed. They feature an electromagnetic rotor and a stator with permanent magnets. The industry-wide compatibility of an Retek brushed dc motor makes integration into your application effortless. You can choose one of our standard options or consult with an application engineer for a more specific solution.